PRODUCTS & SOLUTIONS

CIRA – hot spot detection – Ladle / EAF / LMF

Here, how to avoid this!

ReplicANT

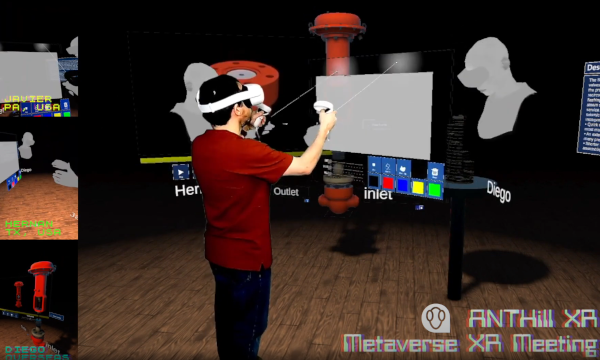

ANTHILL XR – Industrial Metaverse

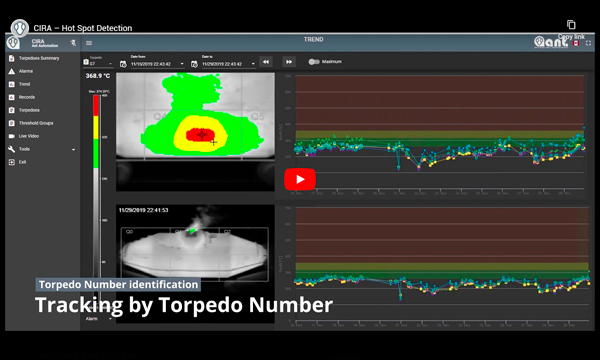

CIRA – hot spot detection – Torpedoes

Industrial Studio

COBOP

CIRA ALL IN ONE

CUSTOMERS

Metals | Oil & Gas | Food Industry

OUR COMPANY

ANT Automation (Applying New Technologies) is a company dedicated to provide high quality engineering services and state-of-the-art software for Industry.

Our company’s head offices are in United States of America, Argentina & España offering services and products worldwide.

We count on a cohesive group of professionals with experience in a wide range of technologies and areas such as Engineering, Math, IT and Metallurgical.

Our mission is to provide innovative products and quality services to our clients using all our capacity and experience to build a profitable firm capable of developing and retaining highly skilled professionals.

We have a strategic plan. It’s called doing things.