WHAT IS ANTHILL XR?

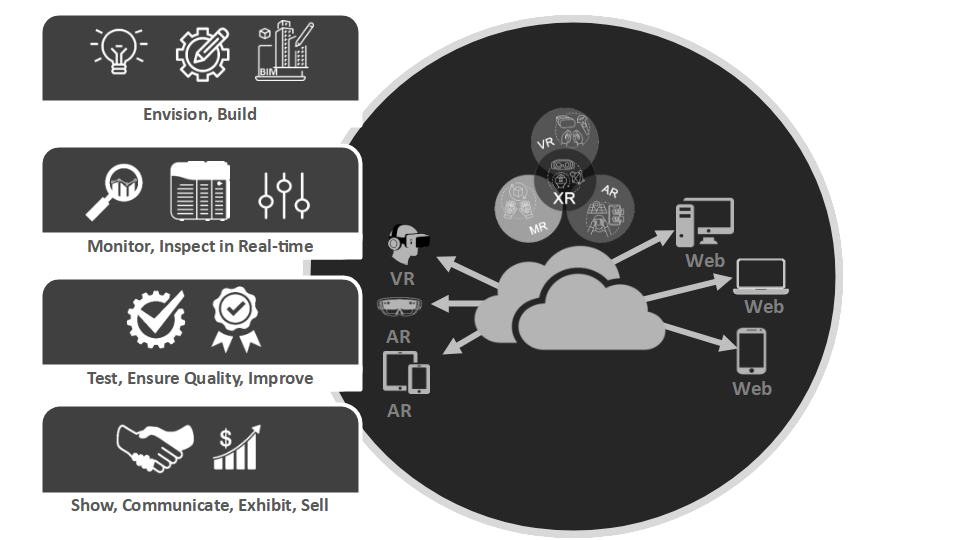

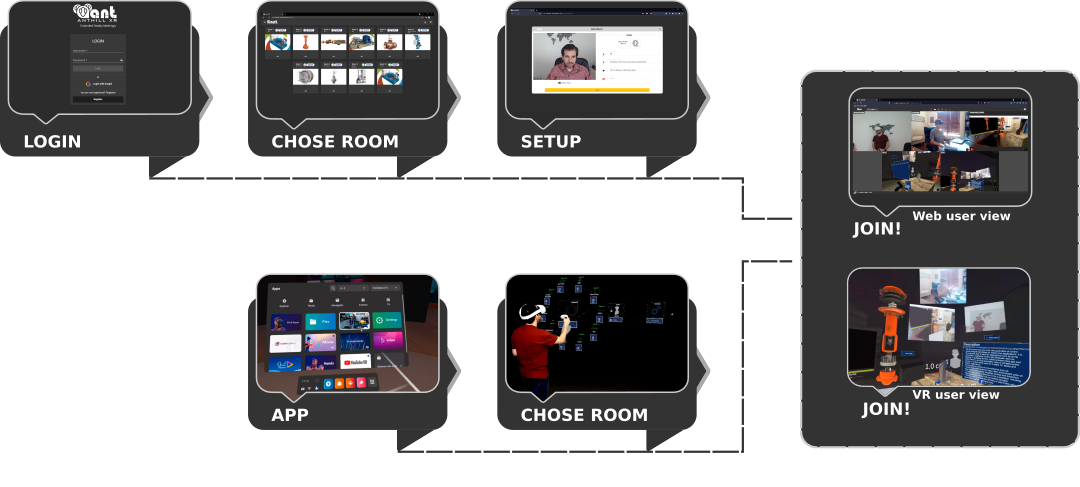

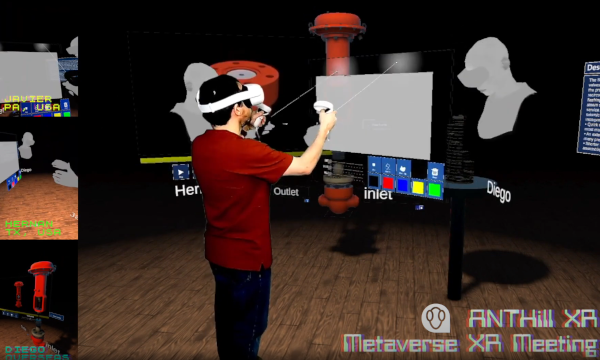

ANTHill XR: is an extended reality (XR) meeting and collaboration platform for industrial applications to display, train people, visualize plant / line status in real-time or perform maintenance.

Extended Reality (XR) is an umbrella term for all immersive technologies: Augmented Reality (AR), Virtual Reality (VR), Mixed Reality (MR), and the ones to come.

WHAT IS THIS FOR, AND DO I NEED TO DO?

If you want to visualize, monitor, show, or test your product, machine, production line, or your Building Information Modeling (BIM), immersed in a collaborative extended reality environment,

we are the company that will help you do it the right way.

In virtual reality, feel, experience, visualize your 3D design, and show it to your team, collaborators, and partners before going into production. You will save money by detecting design flaws in early stages of design. Observe it in AR in the real location where it will be installed or modified.

We can connect your floor plant PLCs or controllers to the XR platform so that you can monitor status in real-time in an immersed environment, both in AR and VR.

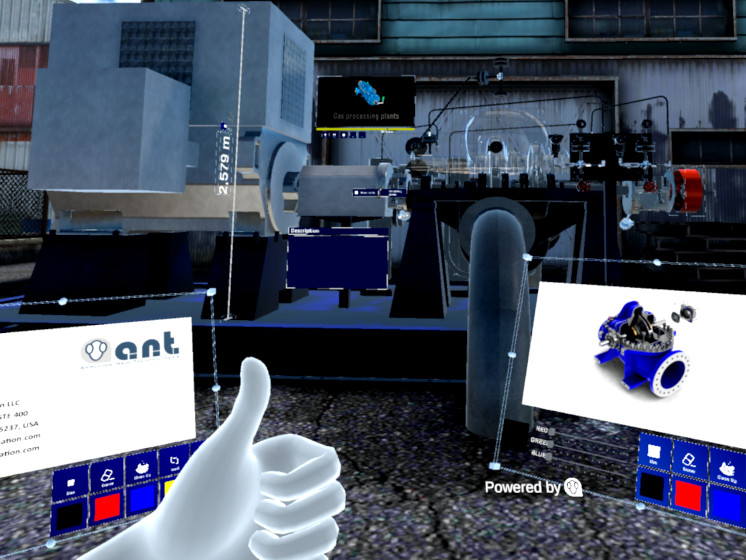

Use virtual reality VR to go to a trade show without spending money and time transporting, installing, and moving machinery or parts of machinery, or production lines. In the tradeshow, you will be able to show your machinery or line in a way that was not possible before, with interactions & operation, movements, in a physics-based simulation. Connect yourself as a trainer to guide the potential customer in the tour. You can connect with another VR headset, or with your cellphone or tablet and appear inside the simulation.

By creating a Digital Twin of machines and entire production lines, you can test the system, connect to actual controllers and do a QA of your automation components and programs.

DIFFERENT SCENARIOS WHERE TO USE ANTHILL XR

Go beyond with Mixed Reality in real time to attract even more and engage “just watching” people.

EXTENDED VISION: XR CRITICAL AREAS

There are three main critical areas to implement collaborative XR (VR+AR+MR): Engineering Design, Maintenance & Training, Sales & Marketing.

It provides a more cost-effective and collaborative product or production line design or infrastructure design and development + Commissioning + Simulation (Digital Twins and Synthetic Environments). It has a significant ROI: by building products, process lines and using VR for continuous improvement of process lines, virtually versus physical builds will save money every year. VR-assisted validation is a tool that provides a more accurate and perceptive QA enabling virtual product testing, conducting to a better iterating design.

More efficient and effective maintenance and training AR & VR solutions help to dramatically reduce the number of errors made by recruits on maintenance tasks to virtually zero. Found the potential or XR of reducing training time by 50 percent over conventional on-the-job training. VR can save as much as one-third of the training cost.

More engaging sales and marketing increasing tradeshow booth leads and retail engagement by 35 percent (based in our ANT – FPSA / Chicago Convention Center and all AISTech every year, since 2014)

A HoloLens 2 user is streaming the actual video with the augmented reality and talking with another person connected to the internet with a cell phone and with another user, immersed in the same scenario, but with an untethered VR headset.

This opens a wide range of possibilities for maintenance and remote assistance.

We have a strategic plan. It’s called doing things.